Each employee will have a better idea of what is expected from them, and know what orders need to be prioritized. When looking for functionality in a production scheduling software, small manufacturers should focus the most on organizing tasks for your staff and having a visual interface.

PRODUCTION SCHEDULING SOFTWARE FREE MANUAL

This is due to the level of manual data-entry that is required, your staff can be spending more time keying in information (and potentially committing errors).

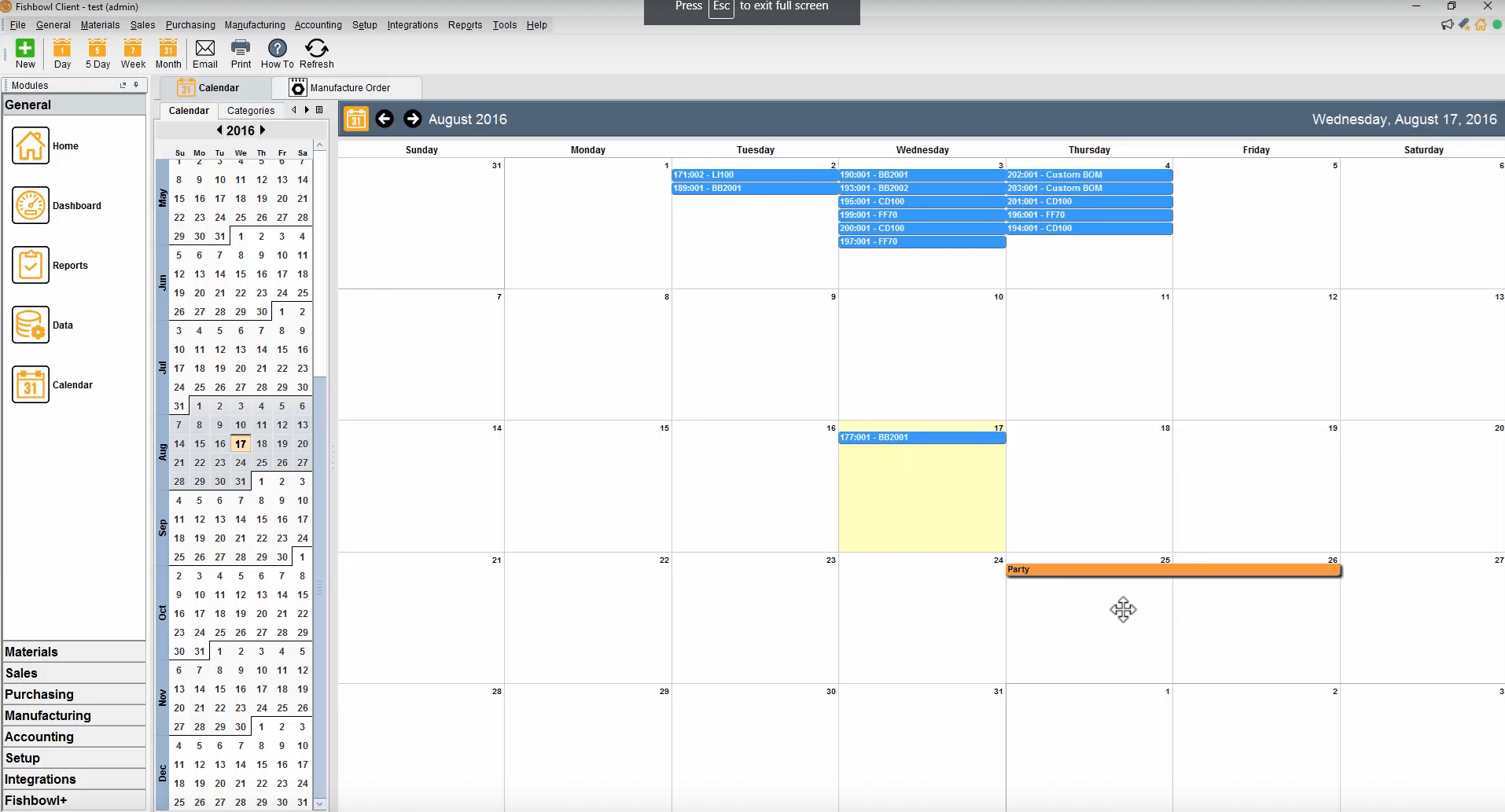

Adjust schedules in real-time when unexpected bottlenecks occur. Capacity planning: Determine the production capacity needed to meet the demand for your products.Drag-and-drop capabilities: A visual approach to scheduling lets you drag and drop orders to different time slots throughout your schedule to see if your production team can fit the manufacturing job at that time or what possible effects it may have on your bottom line.

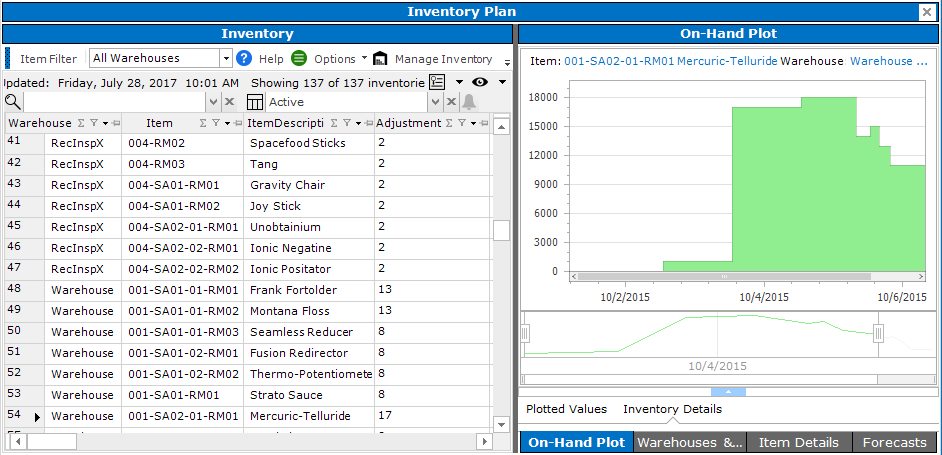

Find the production window that will push orders out the fastest without strain on your employees or resources. Find the one most efficient for your business by syncing resource availability and any constraints. "What-if" analysis: Test out various production schedules by moving orders to different time slots via drag-and-drop functionality.Gantt charts: Create bar charts that show a project schedule illustrating the dependency relations between pending jobs, ongoing jobs, and the employees scheduled to work during those times.A production schedule in MRPEasy shows upcoming operations. It will look at the bill of materials, purchase orders, and current stock, to ensure you have the proper items reserved or the purchase order generated to complete the order.Īlso known as advanced planning and scheduling software (APS), production scheduling software for job shops is used in situations where traditional methods of demand forecasting and production planning (such as MRP software) have fallen short. Production scheduling software helps you convert customer orders into manufacturing orders. Production scheduling software enables manufacturers to create a highly detailed master production schedule that accounts for resource, staffing, and inventory needs in order to complete and optimize production. Production scheduling software helps plan production on your shop floor by determining the need for materials and capacity in order to complete a manufacturing production order. What Is Production Scheduling Software?.

0 kommentar(er)

0 kommentar(er)